Meet my new best friend, the radiant barrier.

The barrier and I have an intimate relationship with the crawlspace beneath my house as I recently decided to conduct an experiment…

At one point last winter we got a reading of 48 degrees in our home, a few inches above the un-insulated wood fl oor. As I’m sure you can imagine, that makes for some REALLY cold feet! Now that we have a little one crawling around I felt the situation required remedy…

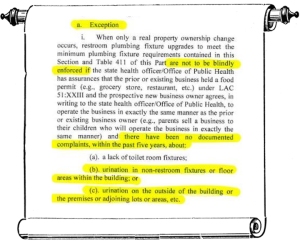

At one point, we received a recommendation of putting rigid board insulation under the fl oor joists to create a continuous air barrier and to acquire some insulative value (note: there is no subfl oor, there are cracks in wood fl oor, etc). Implication being, this might not only be cheaper than spray foam but would also allow for easier inspection/repair of termite damage… should the need arise. Eh-hem.

This is an experiment I volunteered to undertake on my own (meaning, I would do the installation). When I got to the store to purchase board insulation I quickly realized that installing 4 x 8 sheets of this material, in the crawl space, might get a little cumbersome considering the clearance on the side of my house is approximately 2 feet. Good thing there were rolls of radiant barrier nearby: I had not previously considered the material.

Higher R-value than a 1/2 sheet of board insulation AND easier to install? I’m in! So, home I went, cordoned off one room from below and installed a few rolls of the radiant barrier. With the aid of my husband, we monitored air temps in the house, ran the heat and carefully watched the rate at which our inside air temps decreased in the control room and in the experiment room.

Sure enough, the rate at which heat dissipated in the experimet room was slower than that of the control room! Phew!!!

…then again, I have my work cut out for me on the rest of the house!

UPDATE (from a reader):

I received this lovely email reply…

“Good morning Lynn,

I love the article about radiant barrier in this month’s newsletter and can though roughly appreciate what you were going through. Just before I started attending CSI-NOLA meetings in 2009, I studied reflective radiant heat barriers at length and wound up writing what equated to a white paper on the subject so I could explain the theory, process and results to [name withheld] for use in the [name withheld] Building.

We can honestly say that few architects actually practice what we preach when it comes to implementation of thermo conductivity theory. By simply installing a radiant barrier, engineered thickness and total composition specific to the project, we were able to shift the dew point from just behind the interior drywall to the outer portion of the exterior wall. Effectively transferring the moisture causing radiant heat to a point of neutrality. At 90-95% radiant heat reflectivity, relatively inexpensive and ease of installation, we should include it in all of our designs.

Please tell all I said hi.”